Fully automated production line to maintain high precision and productivity

Automated assembly line in clean room Automated assembly line in clean room |  Organized movement production Organized movement production |  Precision metal parts press process Precision metal parts press process |

Time Module Ltd. uses necessary cookies to ensure that we give you the best on our website. In order to do so, we need your consent. By continuing to use this site or by clicking “Accept & Close” you are consenting to the use of cookies. More info can be found in our Website Privacy Policy。

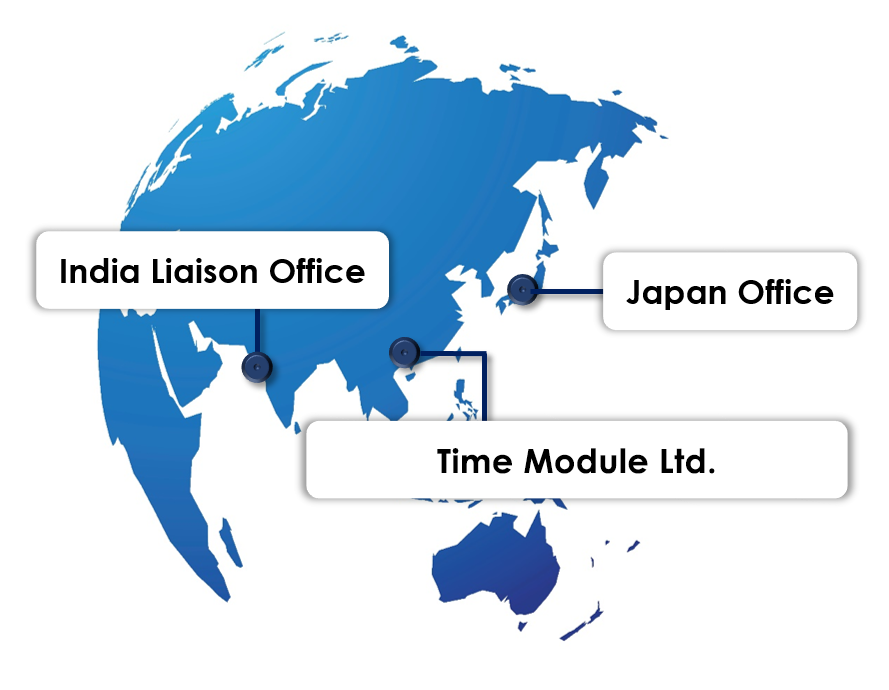

In 1987 we began our journey in Ginza, Tokyo, Japan as “Time Module Inc. (TMI)”. Since then, we have worked with our affiliated factories in designing, developing, and producing a diverse and innovative range of watch movements for clients across the global watch industry.

We started the business through the newly established company “Time Module Inc.” in Ginza, Japan.

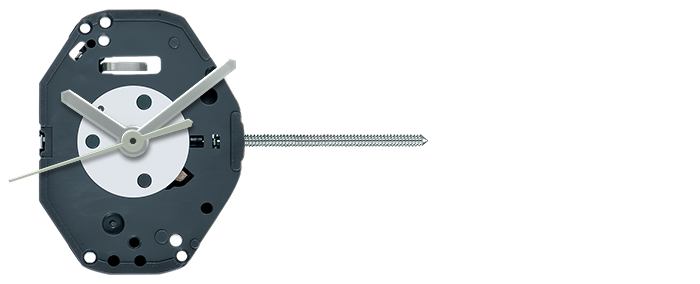

PC21, our first regular quartz movements, was launched.

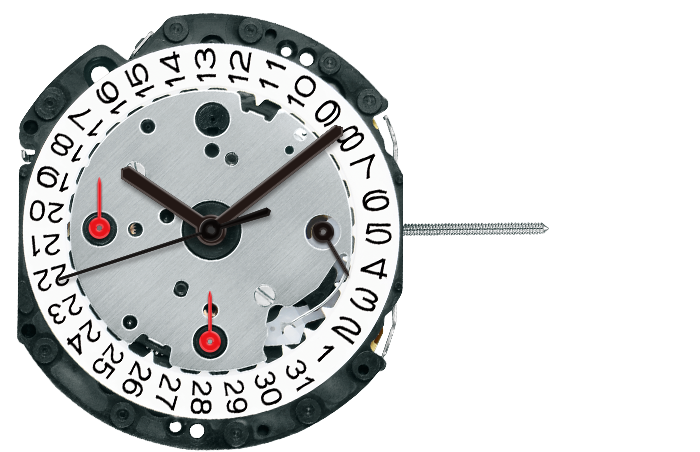

VD5 series, the standard chronograph movements, were launched.

We set up an office in Hong Kong (SAR of China) to actively expand international business.

VC series, the slim and extra small movements, were launched.

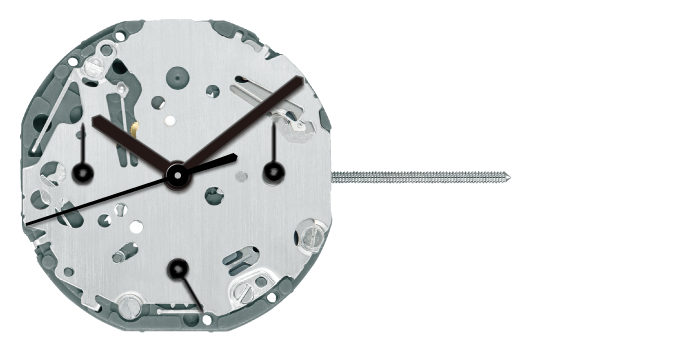

VJ series, the slim movements, were launched.

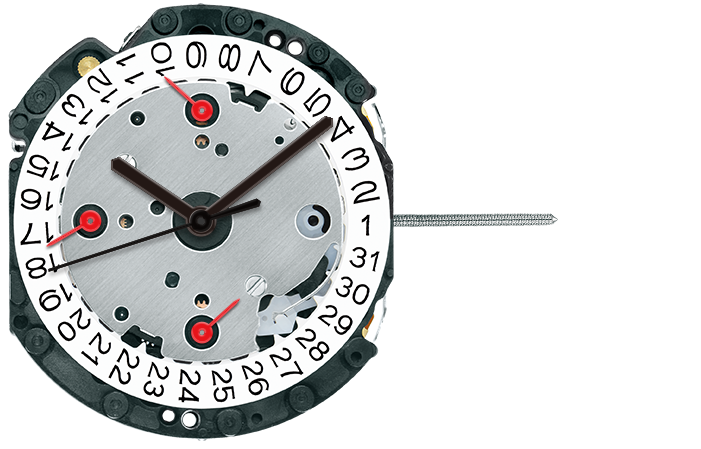

VD7&VD8 series, the multi-eye (2 centre hands) movements, were launched.

All quartz movements started conforming to RoHS directive to protect the environment and public health.

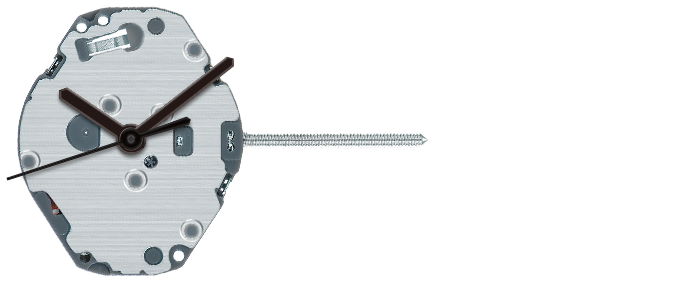

NH series, the standard mechanical movements, were launched.

All quartz movements are equipped with mercury-free and lead-free batteries in pursuit to protect the environment.

VK series, the premium quartz chronograph movements, were launched.

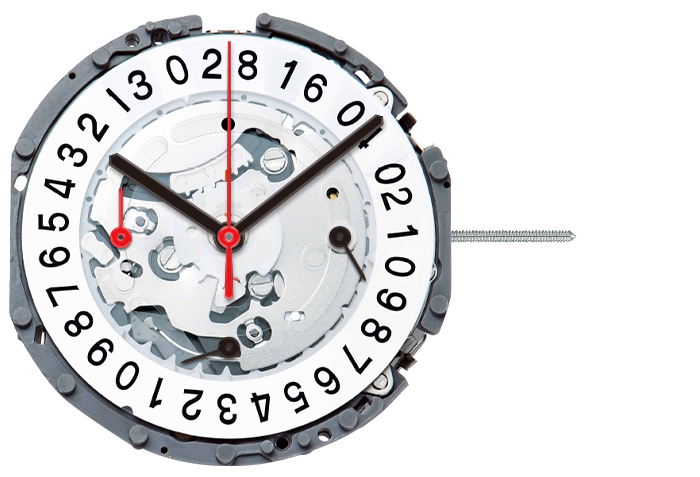

VD3 series, the dual time movements, were launched.

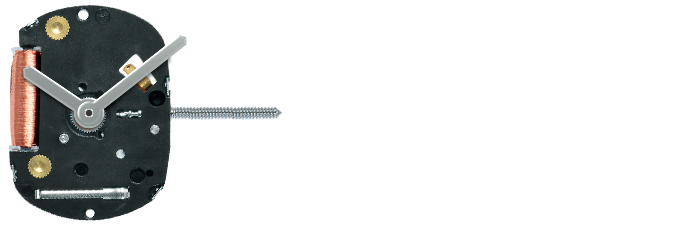

VH series, the sweep second movements, were launched.

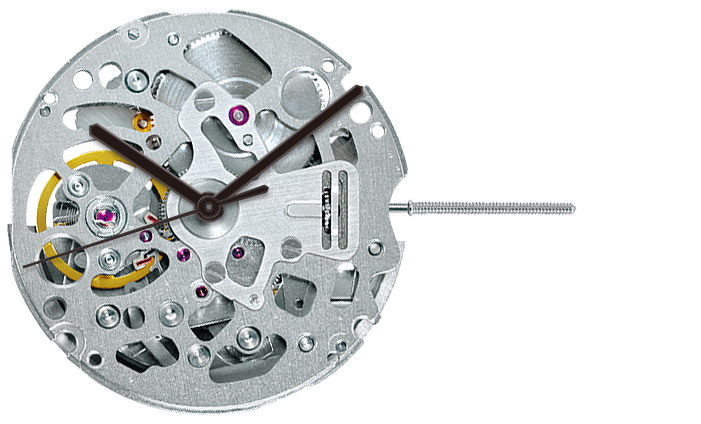

NH7 series, the skeleton mechanical movements, were launched.

Entering a new era, we have changed the product marking to "TMI" since 2020 to unify it with the company's trade name and strengthen the brand recognition of TMI movements. In order to satisfy the market demand, we will strive continuously to provide stable and high-quality products and services to global customers. .

Entering a new era, we have changed the product marking to "TMI" since 2020 to unify it with the company's trade name and strengthen the brand recognition of TMI movements. In order to satisfy the market demand, we will strive continuously to provide stable and high-quality products and services to global customers. .

NH34, the GMT mechanical movement was launched.

From R&D, material development, key parts processing, movement assembling to quality inspection, all processes are handled in-house by our Group companies under a stringent integrated production system. We work closely with one another in order to stably supply high-quality, cost-effective products to the market.

In-house key parts production for full control of parts supply and quality

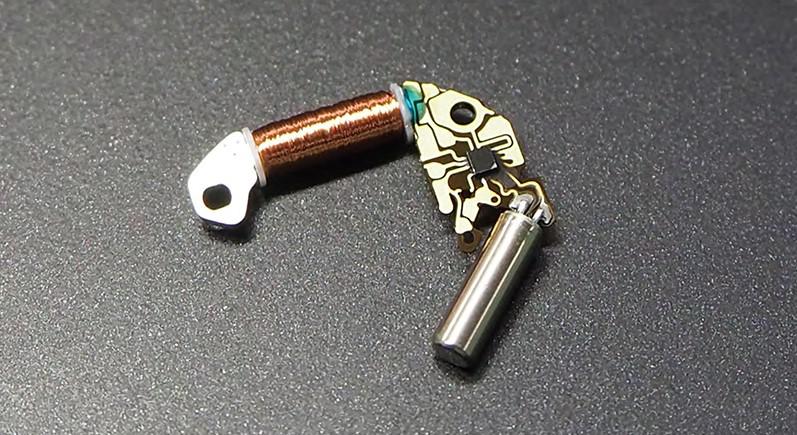

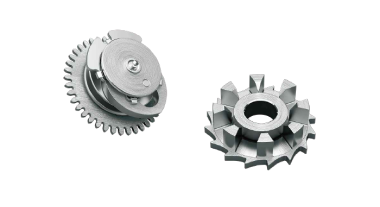

Pressing machine process |  Quartz crystal mounting |  Coil block |

|

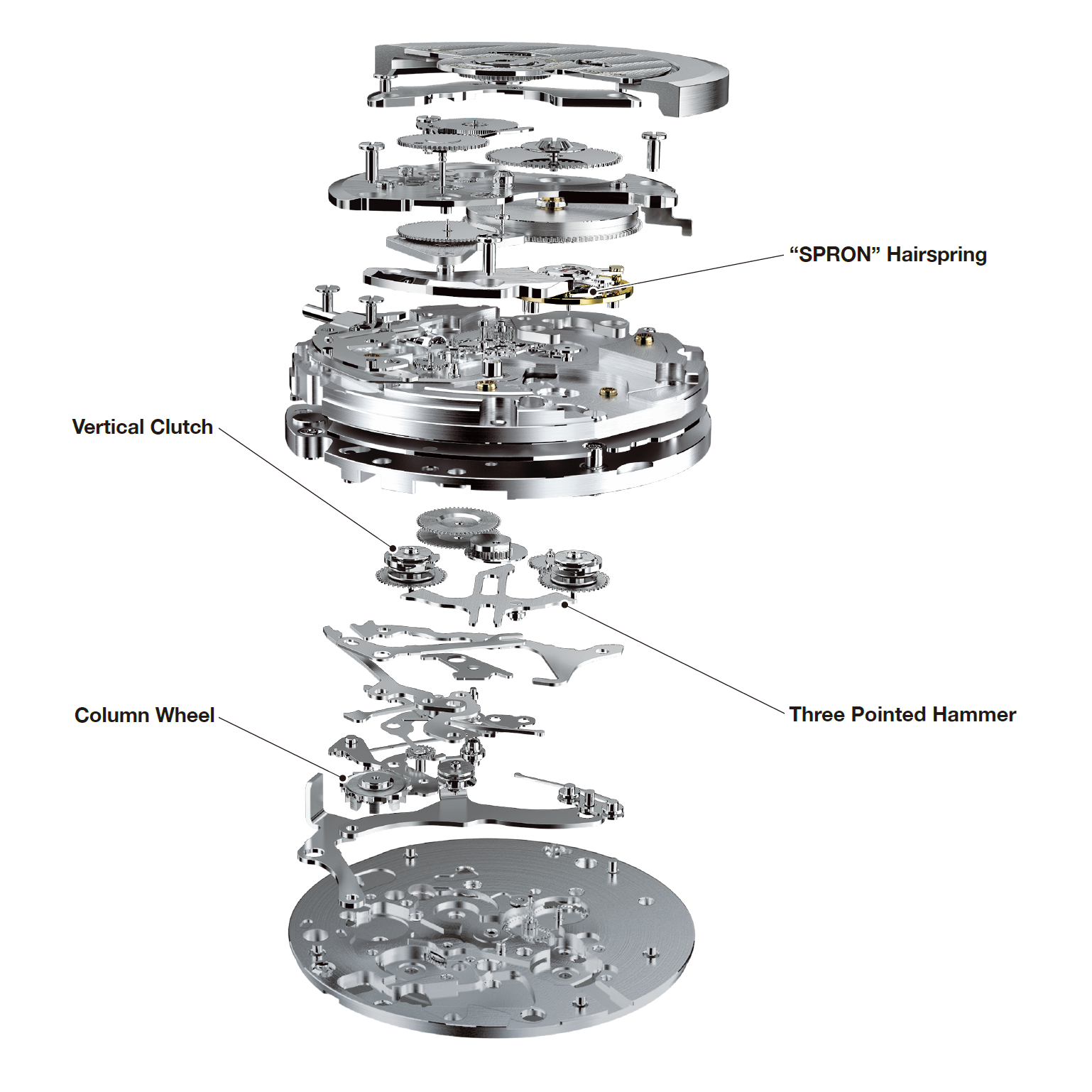

Vertical Clutch for power transmission Vertical Clutch for power transmissionColumn wheel for chronograph coordination |  "SPRON" Hairspring with superior elasticity durability, and highly resistant to corrosion and heat. "SPRON" Hairspring with superior elasticity durability, and highly resistant to corrosion and heat. |  Three Pointed Hammer synchronizes the "Instant Zero Reset" motion of chronograph hands Three Pointed Hammer synchronizes the "Instant Zero Reset" motion of chronograph hands |

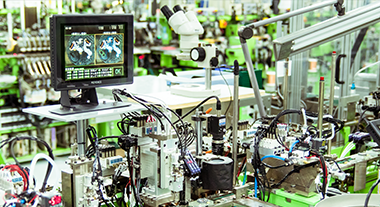

Fully automated production line to maintain high precision and productivity

Automated assembly line in clean room Automated assembly line in clean room |  Organized movement production Organized movement production |  Precision metal parts press process Precision metal parts press process |

From R&D to delivery, the whole production process is under a thorough Total Quality Management System. All of our watch movements are manufactured to the high standard of reliability stipulated by ISO 9001/14001 series.

Vision inspection system Vision inspection system |  3D measurement 3D measurement |  In line electrial characterization In line electrial characterization |

We strive as a whole to contribute to the sustainable development of the society